OEM/Private Label

Recycle Policy

Plastic industry is working hard to improve recycling process because on of the things all of us can do to protect and improve our environment through recycling. Recycled plastics can be used to manufacture a wide variety of new products. As trend change worldwide, we are also focusing to develop all our packaging to be recyclable or reusable in coming future.

Established in 1986, Appollo Houseware has built strong partnerships with customers based on integrity, responsibility, and ingenuity. Our expertise, design capabilities, and advanced technology ensure timely and successful project completion. Early customer involvement in product design is crucial for success. Leading OEMs across industries seek our attention to detail and expertise. We continually improve our people, procedures, and technologies to enhance customer satisfaction. Through training and embracing emerging technologies, we deliver high-value products that exceed expectations. At Appollo Houseware, customer satisfaction is our top priority, driving us to excel in all aspects of our business.

Our in-house production capacity

| S.no | Machines Processes | Materials Usage | Products Formed |

|---|---|---|---|

| 01 | Plastic Injection Moulding | PP, CO-PP, ABS, PMMA, PS, AS, POM | Pet Preforms, Caps and Closures, Ice Cream & Paint Buckets, Food Containers, Cream Jars & Cutlery |

| 02 | Plastic Blow Moulding | PP, PP-RANDOM, HDPE, PC | Shampoo, Lotion & Oil Bottles, Milk Containers, Jerry Cans, Storage Tanks, Plastic Drums & Tubs |

| 03 | Plastic Injection Blow Moulding | PET, PC | Bottles for Water, Juices & Soft Drinks, Cooking Oil Bottles & Chemical Containers |

| 04 | Plastic Compression Moulding | PP, HIMS, CO-PP, PPS | Plastic Trays & Caps, Dinnerware, Buttons, Knobs, Electrical Parts & Automotive Parts |

| 05 | Plastic Thermoforming | PP, ABS, HIPS, HDPE, PET | Disposable Tea & Coffee Cups, Trays & Platters, Salad Containers, Disposable Tableware, Cookies & Cake Trays |

Our Services

GE corporation provides full range service to our customers, which includes:

- New Product & Mould Development

- Designing & Rapid Prototyping

- New Innovation & Customization

- High Quality Product

- Competitive Price

- Packing & Delivery all over Pakistan

- Value Added Services

- Hot Foil Stamping

- Screen Printing

- Heat Transfer

- In-Mould Labeling (IML)

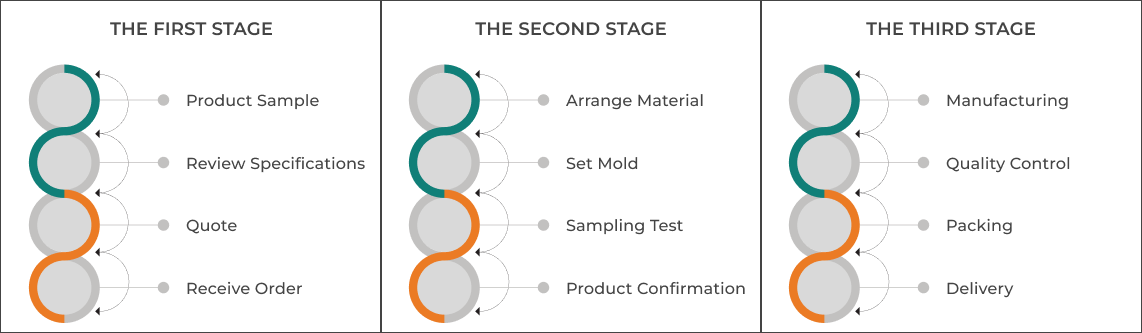

Our Process

GE corporation provides a whole package service to all clients upto their satisfaction from sample assessment, mould design & development, sampling, products bulk production, quality control, packaging and to final delivery.

Products

We have expertise in producing multiple plastic products for our OEM Partners / Customers

- PREFORMS

- |

- BOTTLES

- |

- JARS

- |

- CONTAINERS

- |

- CAPS & CLOSURES

- |

- JERRY CANS

- |

- BUCKET

PREFORM PRODUCTION

EDIBLE OIL PRODUCTS

PAINT INDUSTRY PRODUCTS

PERSONAL CARE PRODUCTS

PHARMACEUTICALS PRODUCTS

CONSUMER CLEANING PRODUCTS

PREMIUM SOFT DRINK AND WATER PRODUCTS

INDUSTRAIL, AUTOMOTIVE & AGRICULTURAL PRODUCTS

Environmental Policy

Appollo Housware focuses on thermoplastics, because they are the most ecologically and economically friendly materials on the market. They are long-living, robust, can be processed without any additives such as formaldehyde or softeners and can be completely recycled. The processing of thermoplastics uses up to 90% less energy than, for example, the production of glass, ceramics or aluminum.

Recycle Policy

Plastic industry is working hard to improve recycling process because on of the things all of us can do to protect and improve our environment through recycling. Recycled plastics can be used to manufacture a wide variety of new products. As trend change worldwide, we are also focusing to develop all our packaging to be recyclable or reusable in coming future.